Automated,

Menu Driven Drawings We make

automated drawing sets for our customers. Here is an extremely successful

example. These

techniques have been useful when large quantities of similar drawings have

to be created. In this case, a detailed drawing for a moment foundation,

like that used in a pier or a large sign pole, can be commissioned in 15

minutes or less once the base drawing is set up. This compares favorably

with 2 to 4 hours for a unique structural drawing. The customer using this drawing set freed up drafting resources,

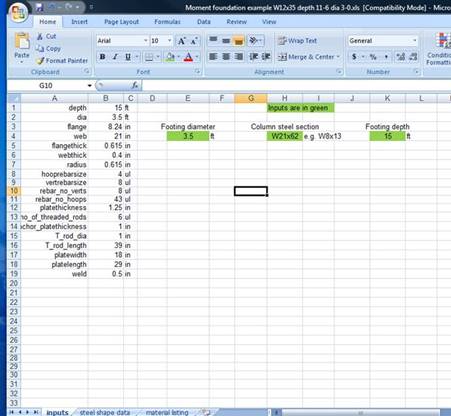

since the only values to change were selected from a drop-down list on a

Microsoft Excel spreadsheet. The bolting, base plate, anchor plates and

rebar were determined in advance by engineering, and change with the size

of the column and foundation. The changes are reflected in the

drawing without having to change leader notes, dimension lines, or any

other drawing parameter. This

particular automated drawing made it possible to crank out hundred of

drawings for an installation crew, and the crew always knew how much rebar

to make up and how much concrete to order. This

drawing series also enabled fast turnaround on installation quotes, and

eliminated lag time between sales, engineering and field services. We can

also automate sheet metal drawings so that the flat pattern, complete with

bend allowances, can be sent to a CNC laser or turret punch, or a complex

milled part can be interpreted by CAM software for use in a CNC mill.

Entire assemblies can be driven from menus to create instructions for the

factory floor or service manuals. A few

simple steps generate the drawing: Open the

Autodesk Inventor part, assembly, and drawing files, as well as the MS

Excel spreadsheet. Select

the column size, footing diameter and footing depth desired from the drop

down menu in the MS Excel spreadsheet, and hit “Save”. Refresh

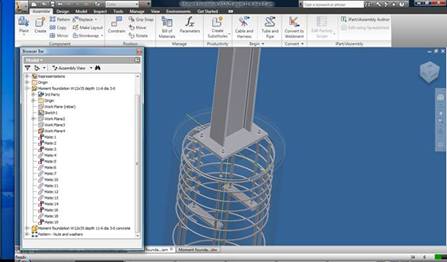

and save the part, assembly and drawing in Inventor. The proper solid model

now appears. Print it

out…use it for quotes (there is a complete, auto generated BOM and bolting

spec in the drawing), code approvals and construction. The weld

specifications are also listed in this example. The drawing is in a form that

is ready to checked and stamped by a local structural P.E.

Enter the column and footing size in the spreadsheet…

Open and refresh the solid model part and assembly files…

And out pops the drawing, complete with bill of materials.